An In-Depth Look at REPART Batteries Manufacturing

In an era where our daily lives are intricately connected to smartphones, the unsung hero that keeps these devices powered up is often overlooked - the phone battery.

Ever wondered how these essential power sources are created?

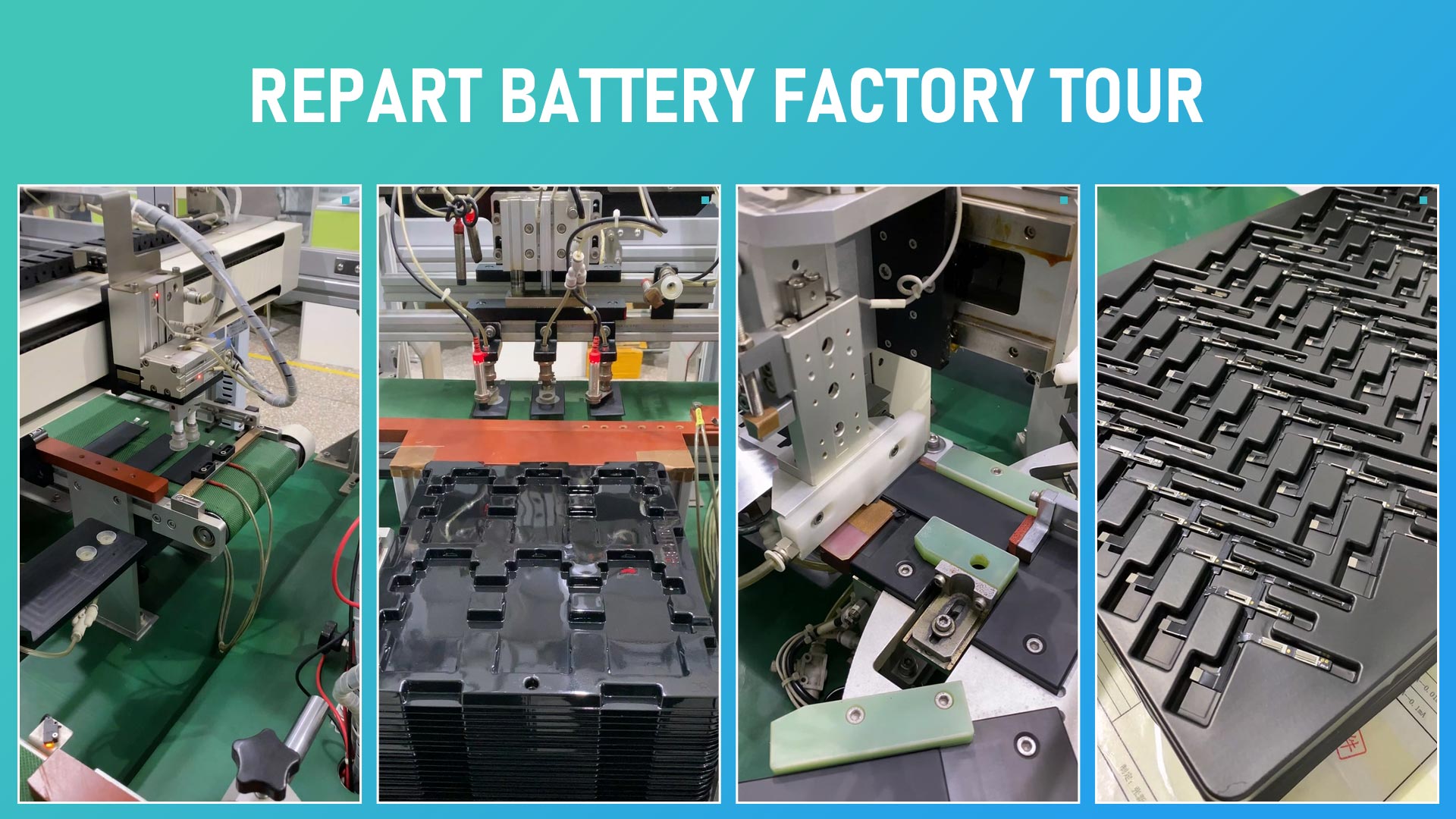

Join us on an exciting virtual tour of a phone battery factory, where we'll unveil the remarkable journey of crafting these indispensable devices.

Incoming Material Inspection and Storage

First of all, we will test the incoming battery cells and protection boards.

REPART strictly selects suppliers and sets up professional product control and testing processes.

For unqualified products, REPART will return them or have the supplier rework them. This is to avoid generating e-waste that does not meet basic standards.

REPART follows management regulations for warehousing, real-time monitoring, and maintaining a safe environment for qualified raw materials.

Cell to Battery Steps

After selecting suitable cells and BMS boards, REPART assembled them into the battery.

The steps are as follows:

Battery Cell Preparation

For the incoming battery cells, REPART needs to test the size, appearance, internal resistance, voltage, self-consumption, capacity, and cycle life of the products first.

Laser welding

Laser welding is the most important procedure during the assembling process

Welding the protection board with a laser precisely can definitely avoid unstable battery quality caused by poor welding.

Tape sticking/Board Bending/Forming tape sticking

Complete insulating tape sticking, L-shaped nickel bending, and protection board bending with the help of the three-in-one multi-functional machine.

Complete the forming tape sticking with the specialized machine.

A cosmetic inspection of the semi-finished battery.

Functional Testing / Printing

A precise voltage test and internal resistance test on the semi-finished battery.

Therefore the functional stability of the battery can be ensured.

Final Check

REPART will run function test and cosmetic inspection before shipment. Every single battery you received is qualified and certified.

Conclusion

The above is an explanation of how batteries are manufactured in the REPART battery factory. We welcome customers to the factory for a tour. Our commitment has always been to provide high-quality, durable, and dependable batteries.

Click the link to learn more about our battery products.

-

Posted in

android battery, battery, battery cell, battery features, news, product, quality control, repart battery, repart battery cell, universal battery cell